Tito v3 is the third iteration of Hitchin Hackspaces robot entered into Piwars. Each year we try to improve upon our previous efforts (sometimes successfully) but we definitely learn something each time. This year we have stumbled onto a winning combination of powerful and extremely quick motors from Pololu, paired with 2x pwm 12amp continuous motor controllers to push everything to its limits. Put simply, its narrower, stronger, more powerful, more reliable and better looking that Tito v2 that it replaced.

Tito v3 is the third iteration of Hitchin Hackspaces robot entered into Piwars. Each year we try to improve upon our previous efforts (sometimes successfully) but we definitely learn something each time. This year we have stumbled onto a winning combination of powerful and extremely quick motors from Pololu, paired with 2x pwm 12amp continuous motor controllers to push everything to its limits. Put simply, its narrower, stronger, more powerful, more reliable and better looking that Tito v2 that it replaced.

As you can see from the video above, Tito3 can spin on the spot very quickly (note: playing in the dirt was a LOT of fun).

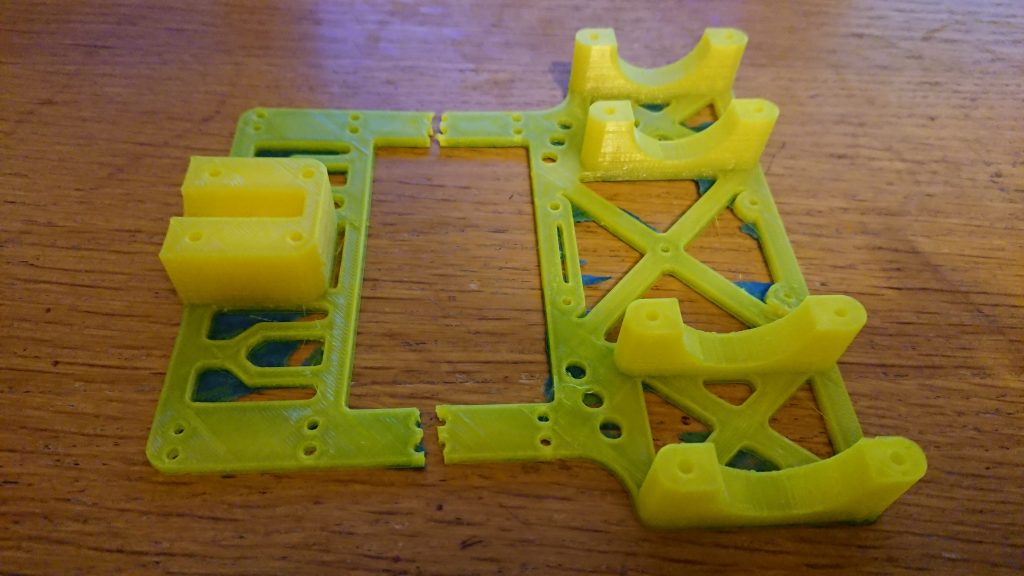

The basic concept of 2018’s version was to keep the drivetrain (motors, controllers, wiring and battery) within a clam shell chassis. We used onshape to design a symmetrical top to bottom frame that would be lightweight and strong as well as clamp firmly the 1000rpm high torque cylindrical motors…a tough challenge in itself.

To keep the weight down and to reduce print time on our Taz4, the chassis needed holes! A style decision made by me was to use triangles as when used properly are a very string shape and look cool 🙂 A few additional features were added to help position battery, mount holes for electronics and allow wiring to be cable tied down.

As you can see from the photo above, the design was an iterative process. Design -> Print -> Break -> goto(10). Not annoying in the slightest that it took about 5 hours to get this printed (mostly as I had the settings wrong to start with) and then it breaks as I’m lifting it from the print bed 🙁

Stopping the motors turning in the clamps was harder. These motors are powerful little bu##ers!

Normally, this type of motor has an L shape metal bracket that screws into the face of the motor around the axle. I didn’t have any of these, nor did I want to include it as it increases weight and adds size that I wouldn’t have control over. I ended up with a simple U shape clamp that would firmly grip around the cylindrical sides using 4x 30mm m3 hex bolts with nyloc nuts all counter sunk into the plastic for looks and to reduce shorting electrical items that might come in contact. This appeared to work first time, but after about 5 minutes driving, I noticed it first pulling left, then noticed dramatic speed reduction. On closer inspection, the front two motors had rotated so far that they had self unplugged from the XT30 connectors, you know, the ones that nearly take your finger nails off when trying to unplug manually. I did say they were high torque motors. This was fixed with a very thin layer of hot glue on the U shape clamps in between the 3D printed plastic and the motor. Just enough to provide a grippy surface for the motors…a solution any maker would be proud of.

Like previous years, we lost about a month in time trying to resolve electrical noise. The video above showing the “square wave” on an oscilloscope that really wasn’t square. We have always used the same cheap “eBay special” 1000rpm motors, and the first ones I used were actually ripped out of Tito2’s carcass. We already knew they were noisy, REALLY noisy. I had hoped moving away from RC car style ESC motor controllers would reduce the impact of this noise….I was wrong. The Pololu motor controllers went into panic mode regularly, especially when motors spun up to full speed. We tried 1x capacitor on each motor across it terminals, no effect, then added more from each terminal to the motor shell. It made it slightly better, but still struggled. It was only after buying 2 more controllers to see if it was a bad batch that I decided to just spend us out of the issue by purchasing official Pololu 1000rpm equivalents. The noise went away immediately, leaving me both happy and annoyed that I hadn’t done it sooner. Silver lining, I now had enough equipment to make a second bot so my team mates could have a second bot to test and work on whilst I did the same.

The autonomous challenges, like previous years were hard. But if it were easy, it wouldn’t be fun. This year focused on “vision” sensors for at least one of the tasks. Others still relied on distance sensors. We used time of flight (TOF) laser sensors which we used the previous year. Unlike the previous year, we now know that they are extremely fragile and are prone to loosing the really tiny 6 pin surface mount chip on them that makes them return sensible results. Last year we didn’t know this until after failing to do almost any autonomous challenges. The sensor module had inbuilt crumple zones in case we hit anything and a reasonable layer of hot glue was applied to reduce impact shock. This worked, all three sensors survived the build, test and actual event!

Testing of autonomous challenges was limited due to family health issues (2 year old son broke his femur a month before the deadline). Martin bravely took over and did amazingly well. We won the “Over the Rainbow” vision challenge and did extremely well in the “Minimal Maze”. The one auto challenge we failed was the “Straight Line Speed Test”. This was the one that I coded 🙁 To be fare, all tests had worked brilliantly. I was repeatedly getting ~2 second run times with no issues. On the day Tito3 repeatedly hit the right wall. I concluded after the event and by looking at the available information that the light gate on the track was at the exact height of my sensors and blinded one side, causing the code to read a high distance and make the bot self center and turn hard right. We’ve now learnt to ignore the first 1/4 second of sensor data and also sanity check returned distances as we know the track width and anything larger is obviously wrong.

RC challenges we very well. Tito3 responded as it had in testing. We narrowly missed winning the “Obstacle Course” but winning the entire balloon popping “PiNoon” competition made up for that.The semi final and final of PiNoon were tense to say the least. All of the other teams and drivers were impressive and I strongly believe I only won due to good luck.

Hardware failure: It wouldn’t be a Piwars without something burning out, and 2018 was no exception. For the “Duck Shoot” challenge, we had a beautiful Nerf turret built from the innards of an old electric Nerf gun all inside a 3D printed housing with magnetic magazine clip. The darts were pushed into the rotating wheels by a servo, and it was this cheap servo that jammed 10 minutes before the challenge and blew the 5v regulator to the turret. #GameOver. We scored VERY low on that challenge 🙁

Overall everyone had fun, we won the PiNoon and Over the Rainbow challenges and we came 4th in the Pro’s category which considering we didn’t get any points for blogging (as I didn’t have time) coupled with the hardware failure on the Duck Shoot challenge, wasn’t bad at all!